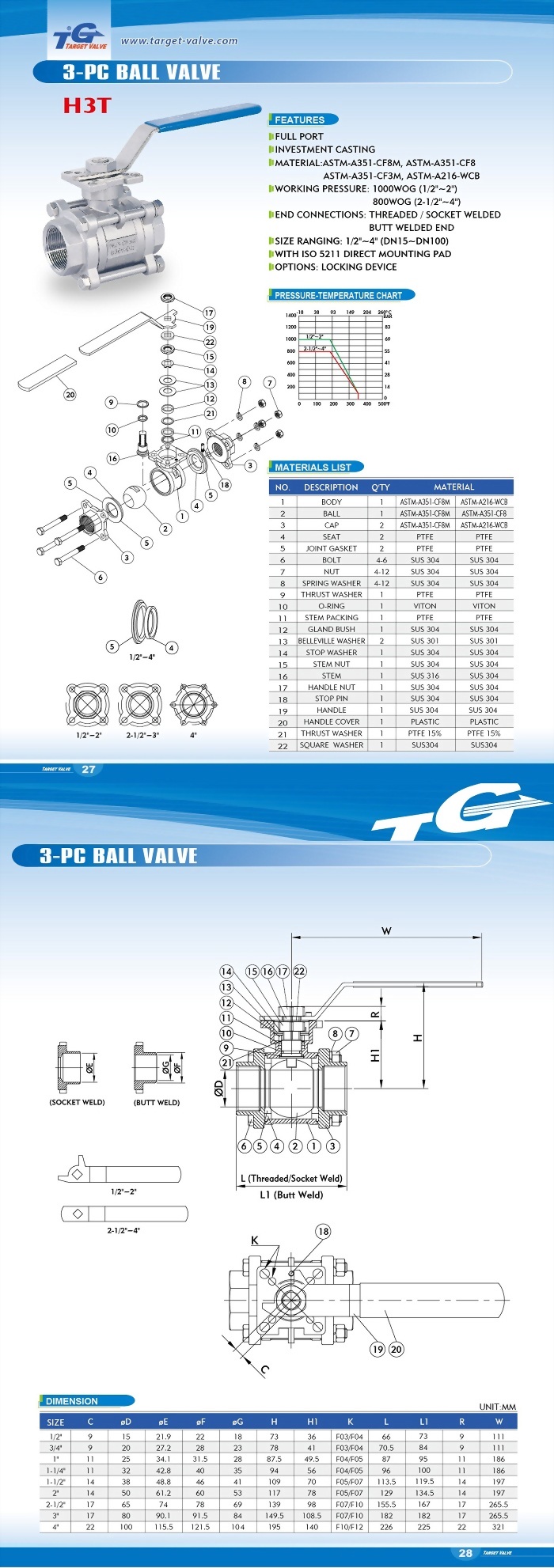

3 PC BALL VALVE - H3T

The 3 piece body construction enables valve in-line maintenance and replacement of internal parts.

This 3-PC ball valve can direct assemble Acting on ball valve.

H3T 2 inch ball valve is more popular valves.

Please select which you want to ask the following product specifications:

| *Selection: |

3-PC BALL VALVE

FULL PORT

INVESTMENT CASTING

PTFE SEAT

WITH ISO 5211 DIRECT MOUNTING PAD

WORKING PRESSURE: 1000 WOG / PN63 (½" - 2" )

800 WOG / PN40 (2-½" - 4" )

END CONNECTION: ( H3T) / ( H3SW ) / ( H3BW)

FEMALE THREADED ENDS / SOCKET WELED / BUTT WELDED

AVAILABLE SIZE: ½" - 4"

(DN15 - DN100)

MATERIAL: CF8M (SS316)

ACCEPTABLE OTHER MATERIAL OF CF8 (SS304) / CF3M (SS316L) / WCB WITH MINIMUM ORDER QUANTITY.

OPTIONS : LEVER OPERATION (-NL) / LOCKING OPERATION (-HL) / BARE STEM

SPRING RETURN ACTUATORS (-SA) / DOUBLE ACTING ACTUATORS (-DA) / ELECTRIC ACTUATORS (-EA)

The sizing of pneumatic actuators has been done considering a minimum supply pressure of 4.5 bar.

LIMIT SWITCH / SOLENOID VALVE

REPAIR KIT => SEAT, JOINT GASKET, THRUST WASHER, O-RING, STEM PACKING, THRUST WASHER

A full port or more commonly known full bore ball valve has an over-sized ball so that the hole in the ball is the same size as the pipeline resulting in lower friction loss. Flow is unrestricted but the valve is larger and more expensive so this is only used where free flow is required, for example in pipelines which require pigging.

Floating Ball Valve– A floating ball valve is not held in place by a trunnion, and instead is attached only to the stem. This sometimes causes the ball to float slightly downstream. However, when this happens, the ball presses against the seat, creating a positive seal.

Production of chemicals,

Gas Industry, Oil refineries, Water treatment,

Industrial Facilities,

Building Facilities,